“Can you explain the effects of abrasive wear and how you can determine if it is occurring?”

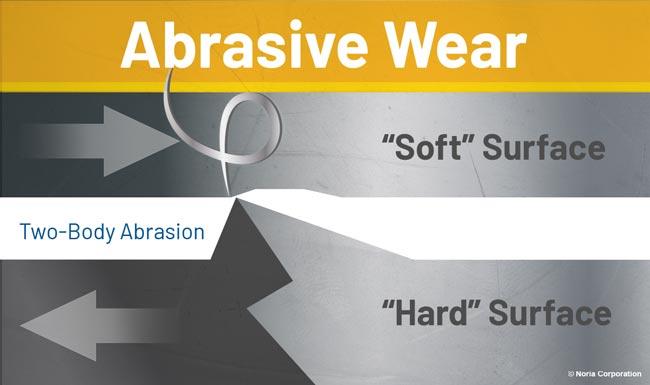

There are two basic forms of abrasive wear: two-body abrasion and three-body abrasion. A simple description of two-body abrasion would be a hard, rotating surface cutting into a soft, fixed surface, like a shaft running over a sleeve bearing. Imagine taking a car key to the side of a car. The key rips into the car’s surface, causing damage.

The hard particles that do the cutting on machines are called asperities. These are slightly raised imperfections that are found on rotating components. This type of abrasion is mostly seen when machines are starting up or heavily loaded. These conditions allow asperities to come in contact with the softer component, because the lack of speed reduces separation. Once the machine is up to speed, the lubricant’s viscosity will protect the machine parts by keeping them separated.

Another common cause of this type of wear is using a lubricant with too low of a viscosity, as it won’t allow the machine parts to be fully separated. To prevent two-body abrasion, additives existing in the oil can be used to protect surfaces during boundary lubrication. The right lubricant viscosity will also help keep full separation.

Three-body abrasion can be explained as a hard particle (the third body) moving between two surfaces. These microscopic particles are about the same size as the lubricating film, allowing them to scrape through the small clearance between lubricating components. As this happens, the particle can cause damage to both soft surfaces.

The third body creating the damage can be introduced in several ways. The particle may have been built in by the manufacturer, ingested through an open hatch or breather vent, or even added to the machine via a dirty lubricant.

There are numerous ways to combat these harmful contaminants. Any time a new machine is acquired, it should be flushed to remove any built-in debris. Also, close all hatches and open ports on the machine. Adding a filtration device can reduce the number of contaminants as well.

Different methods can be used to determine if your machine has undergone abrasive wear. A visual inspection of the machine parts should be the first step in accessing the equipment for abrasive wear. However, sometimes the human eye cannot see the microscopic damage being done. The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. This type of analysis uses heavy magnification to look for tiny particles that could cause damage.